- This topic is empty.

-

AuthorPosts

-

2025-05-15 at 6:22 pm #6746

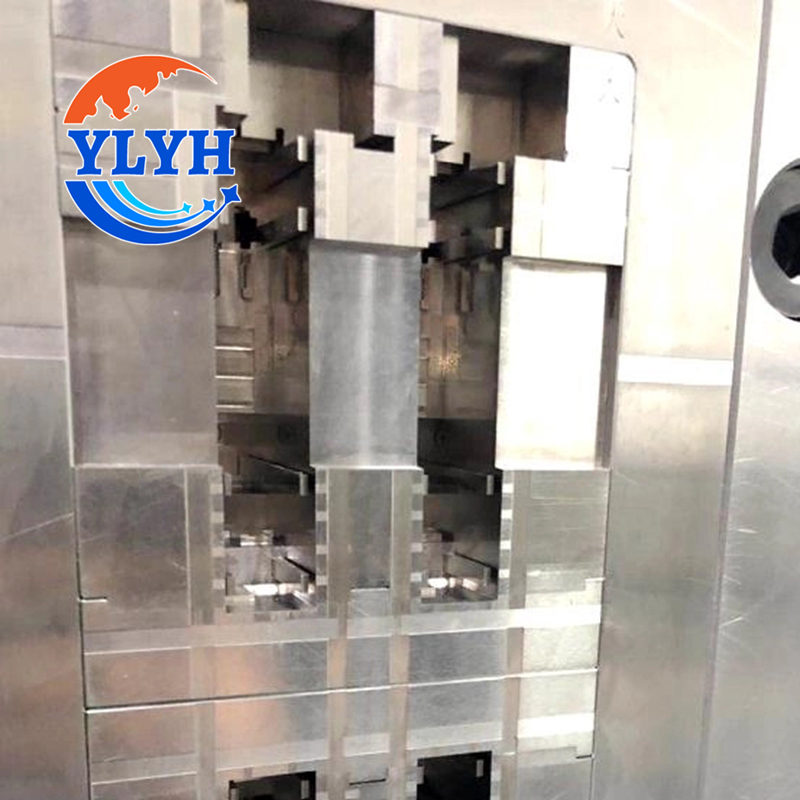

At Shenzhen YLYH Technology Co., Ltd., we specialize in the design and production of high precision automotive injection moulds that deliver unmatched performance and longevity for durable plastic automotive parts. Our advanced tooling solutions are engineered to meet the rigorous standards of the modern automotive industry, ensuring every mould we create results in durable auto parts molding with exceptional dimensional accuracy and mechanical strength.

CNC Machining for Precision Tooling

One of the core pillars of our manufacturing process is CNC precision machining, which allows us to produce mould components with ultra-tight tolerances. By leveraging high-speed CNC equipment, we ensure the base and cavities of each automotive injection moulding tool are perfectly aligned and finely finished. This not only improves the lifespan of the mould but also guarantees the dimensional accuracy of each injected part, critical for components used in automotive assemblies.

EDM (Electrical Discharge Machining) for Complex Geometries

For intricate or difficult-to-machine features, we use EDM (Electrical Discharge Machining). This process is vital for creating deep, narrow slots or complex 3D profiles that conventional machining cannot achieve. EDM ensures a flawless finish in precision areas of the automotive injection mould, enhancing mould functionality and part ejection consistency.

Moldflow Analysis for Design Optimization

Before tooling begins, our engineering team performs comprehensive Moldflow Analysis to simulate the injection process. This analysis allows us to predict material flow, identify potential warpage or air traps, and adjust gate locations and cooling channels accordingly. The result is a fully optimized mould that supports stable, high-quality durable auto parts molding with minimal production defects.

Full Process Quality Control

Quality is at the heart of everything we do. Our full process quality control ensures that every mould component is inspected at multiple stages, from raw material selection to final assembly. We utilize coordinate measuring machines (CMM), hardness testers, and other precision instruments to validate mould integrity and conformity. This guarantees that each durable plastic automotive part produced meets or exceeds client expectations.

Why Choose YLYH for Your Automotive Injection Moulding Needs?

As a dedicated manufacturer with years of experience in automotive injection moulding, we understand the critical role of reliability and repeatability in automotive production. Our moulds are used for both interior and exterior vehicle components, under-the-hood parts, and functional assemblies. Every tool is designed for long service life, high-cycle efficiency, and easy maintenance—ensuring you benefit from lower production costs and consistent product quality.

Whether you require OEM solutions or need support developing a new plastic part from concept to production, Shenzhen YLYH Technology Co., Ltd. is your trusted partner in high precision automotive injection mould development. We combine cutting-edge manufacturing technologies with engineering expertise to deliver moulds that power the future of the automotive industry.

http://www.ylyhmold.com

Shenzhen YLYH Technology Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.