- This topic is empty.

-

AuthorPosts

-

2025-05-15 at 5:48 pm #6742

In global precision optics and multifunctional plastic sheet manufacturing, there are increasing demands for intelligent extrusion equipment with enhanced stability and material adaptability. Jwell Machinery (Suzhou) integrates material science and intelligent equipment technology to launch its new-generation:

3000mm width,0.8-18mm thickness PC/PMMA/PETG/GPPS/ASA five-in-one compatible sheet production line

This production line is specially designed to cope with the large-format sheet market with multiple categories, high standards and high efficiency. lt is a high-end sheet solution integrating "intelligent equipment + material technology + structural technology".

Equipment structure and core advantages

1. High stability extrusion system: adopts patented screw struct-ure design, adapts to materials with different viscosities and thermal stability, realizes uniform mixing and pyrolysis control at the molecular level, and ensures continuous extrusion quality.

2.Wide-width three-roll calendering and constant temperature thickness control: the calendering roller adopts a large-diameter chrome-plated roller, with a high-response PlD temperature control and a multi-section heating system to ensure the thickness consistency and flatness of the sheet.

3. Modular material change structure: one-button switching to process PC, PMMA, PETG, GPPS, ASA and other materials, accurately control the temperature window, and meet the diversified order requirements of different industries.

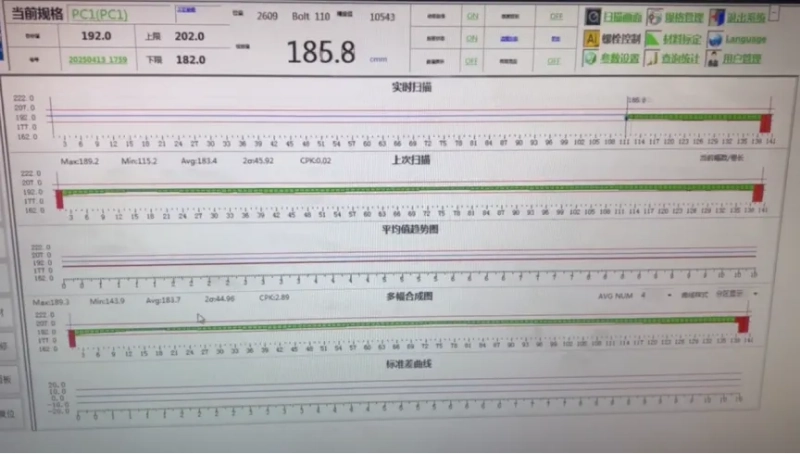

4.Industry 4.0 intelligent monitoring system: equipped with JW remote visualization platform, it realizes real-time upload and historical backtracking of all parameters of temperature, thickness, tension, and operating status.

Material compatibility analysis

• PC(polycarbonate): Bisphenol A structure gives it high impact strength and high temperature resistance. The extrusion process has high requirements for melt shear rate and devolatilization efficiency.The special segmented design of Jwell screw can effectively prevent thermal degradation of molecular chains and ensure light transmittance and mechanical properties.

• PMMA (acrylic): The methyl methacrylate chain structure is rigid, brittle and heat-sensitive. This equipment adopts low shedr design and annealing device to coordinate stress control, which is suitable for optical-grade sheet products.

• PETG: It is sensitive to crystallization and has a narrow thermal stability window, requiring precise temperature control and low shear process. Jinwei's entire line adopts independent temperature control and inteligent dehumidification and drying system to effectively inhibit yellowing and improve product transparency.

• GPPS: The molecules are loosely arranged and the thermal deformation is low. The equipment is equipped with a streamlined die head design to ensure that it does not deform or ripple under a large width.

• ASA: The UV-resistant molecular side chains have strong stability and are suitable for outdoor high temperature and high humidity scenes. The equipment provides double-sided co-extrusion function, which can realize highly weather-resistant sheets with multi-layer structures.

Applicable industries and value manifestation

This equipment is widely used in optical plates, advertising light boxes, building decorative panels, sanitary ware and bathroom, medical trays, electronic insulation sheets, rail transit protective screens and other fields, creating the following value for customers:

√ One-line multi-function: Quickly switch different products and thicknesses to reduce switching costs

√ Intelligent energy saving: High-efficiency drive system + automatic thickness control material saving, comprehensive energy consumption reduced by 15%

√ Long equipment life:Key components such as gearboxes and transmission shafts are made of imported alloy steel, with a design life of more than 15 years

√ High finished product yield: The qualified rate of optical transparent products is > 98%, and high recognition from high-end customers

Wide-format offline coating system

This system is integrated at the downstream of the main extrusion line, tailored for skin-feel panels in furniture and floor-to- ceiling glass in hotels. lt supports coatings like silicone oil, permanent anti-static, anti-fog and anti-fingerprint agents. The precision coating head and tension control system ensure uniform thickness and strong adhesion, delivering superior surface performance.

Jwell Guarantee · Trustworthy

As the world's leading manufacturer of polymer material extrusion equipment, Suzhou Jwell Machinery insists on customer-centricity and technology-centricity, and is committed to creating every intelligent production line with global competitiveness.The 3000mm wide sheet equipment is a strategic achievement of our deep understanding of the development trend of the sheet industry and the integration of material science and intelligent manufacturing.

Welcome to inquire about customized solutions, make an appointment for atrial machine visit, and create a high-end sheet manufacturing future together!

Suzhou Jwell Machinery Co., Ltd.

http://www.jwellplas.com

JWELL -

AuthorPosts

- You must be logged in to reply to this topic.